Save Money with Professional Packaging Machine Repair and Maintenance

Wiki Article

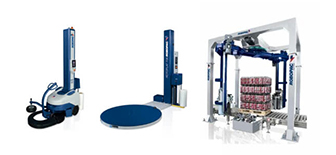

Quick and Reliable Packaging Device Repair Solutions to Decrease Downtime

In the affordable landscape of manufacturing, the efficiency of packaging operations hinges on the reliability of equipment. Quick and trustworthy repair service solutions are important in alleviating downtime, which can lead to significant functional problems and financial losses.Significance of Timely Repair Works

Timely repair work of product packaging devices are vital for maintaining functional performance and decreasing downtime. In the hectic environment of manufacturing and packaging, also small malfunctions can bring about substantial delays and efficiency losses. Dealing with issues immediately makes sure that devices run at their ideal capacity, therefore safeguarding the flow of procedures.In addition, regular and timely upkeep can prevent the rise of small problems right into significant failures, which typically incur higher repair costs and longer downtimes. An aggressive strategy to machine repair work not only protects the integrity of the devices yet additionally improves the general reliability of the assembly line.

Furthermore, prompt repair services add to the longevity of product packaging machinery. Devices that are serviced immediately are less most likely to deal with excessive deterioration, allowing services to maximize their financial investments. This is especially important in industries where high-speed packaging is necessary, as the requirement for regular efficiency is paramount.

Benefits of Reliable Provider

Reputable company play a pivotal duty in guaranteeing the smooth procedure of packaging devices. Their expertise not only improves the effectiveness of repairs but likewise adds dramatically to the durability of equipment. Trusted service suppliers are outfitted with the technological knowledge and experience required to identify problems properly and apply effective remedies promptly. This minimizes the risk of reoccuring issues and makes sure that equipments operate at ideal efficiency levels.

Additionally, a respectable provider uses detailed assistance, including training and support for personnel on maker operation and maintenance best practices. This not just encourages workers however also cultivates a society of safety and security and effectiveness within the organization. In general, the benefits of involving reputable provider extend beyond prompt repair work, favorably affecting the entire operational operations of product packaging processes.

Usual Packaging Maker Issues

In the realm of product packaging procedures, different problems can jeopardize the effectiveness and performance of devices (packaging machine repair). An additional usual concern is misalignment, which can cause jams and irregular product packaging, influencing item top quality and throughput.Electrical issues can additionally interfere with packaging procedures. Damaged electrical wiring or malfunctioning sensors might cause erratic maker habits, triggering hold-ups and increased operational expenses. In addition, software glitches can hinder the device's programming, bring about operational inadequacies.

Inconsistent item flow is another essential issue. This can arise from variations in item weight, size, or form, which may impact the equipment's capacity to deal with products properly. Inadequate training of drivers can exacerbate these issues, as untrained workers may not recognize early signs of breakdown or might abuse the devices.

Attending to these typical packaging machine concerns without delay is essential to keeping performance and you can try here making sure a smooth operation. Regular inspections and aggressive upkeep can considerably reduce these concerns, cultivating a trustworthy packaging environment.

Tips for Minimizing Downtime

To lessen downtime in packaging operations, applying a positive maintenance approach is important. Routinely scheduled upkeep checks can identify possible issues prior to they intensify, ensuring makers operate successfully. Establishing a regimen that includes lubrication, calibration, and examination of vital components can substantially reduce the regularity of unexpected malfunctions.Training personnel to run machinery properly and acknowledge early warning indicators of malfunction can additionally play an essential role. Encouraging operators with the understanding to execute fundamental troubleshooting can protect against minor problems from creating major hold-ups. In addition, maintaining an efficient supply of vital extra components can expedite repair services, as waiting for parts can bring about extended downtime.

Furthermore, recording machine efficiency and upkeep activities can assist recognize patterns and reoccurring troubles, enabling targeted interventions. Incorporating sophisticated tracking modern technologies can give real-time data, enabling predictive maintenance and reducing the danger of unexpected failures.

Finally, promoting open communication between operators and maintenance teams guarantees that any type of irregularities are quickly reported and dealt with. By taking these positive steps, companies can improve operational efficiency and significantly reduce downtime in product packaging procedures.

Choosing the Right Repair Service Service

Selecting the ideal repair work service for product packaging machines is an essential decision that can dramatically affect functional effectiveness. Begin by evaluating the supplier's experience with your particular kind of packaging devices.Following, think about the company's online reputation. Seeking comments from various other companies within your sector can offer understandings into dependability and top quality. Accreditations and collaborations with recognized devices suppliers can find more info also suggest a dedication to quality.

Additionally, examine their action time and schedule. A company who can provide timely assistance lessens downtime and maintains production flow constant. It's also important to make inquiries about warranty and service assurances, which can mirror the self-confidence the company has in their job.

Final Thought

To conclude, the significance of fast and trustworthy product packaging machine fixing services can not be overemphasized, as they play a vital role in decreasing downtime and making sure operational effectiveness. By prioritizing timely repairs and choosing dependable company, services can effectively attend to common problems and keep performance. Executing aggressive maintenance methods and spending in staff training additional boosts the longevity of packaging equipment. Ultimately, a tactical strategy to repair services promotes an extra resilient production atmosphere.Prompt fixings of product packaging equipments are crucial for maintaining operational efficiency and minimizing downtime.Additionally, timely repairs contribute to the longevity of packaging equipment. Learn More Here On the whole, the advantages of involving trustworthy solution suppliers prolong beyond instant repair work, positively impacting the whole functional process of packaging processes.

Report this wiki page